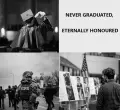

An exhibition commemorating Ukrainian students who could not complete their studies.

The admission process for doctoral study programmes starting on March 1, 2026, has been announced.

We’ve heard your questions and requests — and now you can finally purchase Faculty of Transportation Sciences merchandise through the online store of the CTU Publishing House in Prague!

28.-29. May 2026

Praha, Česká republika

Thursday, December 4, 2025, 09:30-11:00

Na Florenci 25, Praha 1, F007

The Faculty of Transportation offers a wide range of study programs covering all areas of transportation. Whether you are interested in railways, aviation, road transport, or logistics, you will find the right program with us.

Discover the world of transportation through innovative and practically oriented programs.

Take your knowledge to the next level with our master's programs.

Kickstart your journey to scientific discoveries and deeper understanding of transportation.

Imagine a place where not only transportation develops, but also your visions of the future.

In our laboratories and specialized workplaces, we are not afraid to dive into the unknown, whether it is in the field of transportation optimization, autonomous vehicles, railways, designing effective measures, or sustainable transportation solutions.

Studying at the Faculty of Transportation of CTU is not just about theory. Our students experience a unique project-based learning concept that allows them to change the world of transportation even before they graduate. Take a look at some interesting projects we are working on at the faculty.